Another thing is economics. Everyone complains about taxes, prices, and how expensive it is to live any more. I'm not going to go into taxes - that way lies madness. But I can tell you that living has never been cheaper. We live in a country awash in stuff - food, clothing, appliances, machines, cheap crap from China - but it's never enough. $4 t-shirts? Please. We want five for $10, and even then, can we get them on sale? And yet, compared to a world where everything is made by hand - we're talking barely 200 years ago - everything is cheap and plentiful, and we are appallingly ungrateful.

Let's talk clothing. When the Industrial Revolution began, it started with factories making cloth. Why? Because clothing used to be frighteningly expensive. Back in my teaching days I gave a standard lecture, which is about to follow, on the $3,500 shirt, or why peasants owned so little clothing. Here's the way it worked:

NOTE: As of 4/6/16 I have updated the mathematics of this here at this blog post. It's still astounding.

See this guy below, lying asleep under the tree? And the guys still working in the field? They're all wearing a standard medieval shirt. It has a yoke, a bit of smocking and gathering around the neck, armholes, and the wrists would be banded, so they could tie or button them close.

Oh, and in the middle ages, it would be expected that all of the inside sleeves would be finished. This was all done by hand. A practiced seamstress could probably sew it in 7 hours. But that's not all that would go into the making. There's the cloth. A shirt like this would take about 5 yards of cloth, and it would be a fine weave: the Knoxville Museum of Art estimates two inches an hour. So 4(yards)*36(inches)/2 = 72 hours. (I'm a weaver - or at least I used to be - so this sounds accurate to me.) Okay, so hand weaving and hand sewing would take 79 hours. Now the estimate for spinning has always been complex, so stick with me for a minute: Yardage of thread for 4 yards of cloth, one yard wide (although old looms often only wove about 24" wide cloth), and requires 25 threads per inch, so:

9,000 yards would take a while to spin. At a Dark Ages recreation site, they figured out a good spinner could do 4 yards in an hour, so that would be 2,250 hours to make the thread for the weaving. Now, A lot of modern spinners disagree with this figure, saying they can spin much faster than that. So let's say they're right. And we'll say that the spinner is in a hurry to make this thread because the shirt's for her or someone she knows (all spinners were female in medieval times), so we'll say she worked her tail off and did it in 500 hours.

So, 7 hours for sewing, 72 for weaving, 500 for spinning, or 579 hours total to make one shirt. At minimum wage - $7.25 an hour - that shirt would cost $4,197.25.

And that's just a standard shirt.

And that's not counting the work that goes into raising sheep or growing cotton and then making the fiber fit for weaving. Or making the thread for the sewing.

And you'd still need pants (tights or breeches) or a skirt, a bodice or vest, a jacket or cloak, stockings, and, if at all possible, but a rare luxury, shoes.

NOTE (1/30/15) - Please see a further commentary on this piece at: Is Time Money or is Money Time?

NOTE: Back in the pre-industrial days, the making of thread, cloth, and clothing ate up all the time that a woman wasn't spending cooking and cleaning and raising the children. That's why single women were called "spinsters" - spinning thread was their primary job. "I somehow or somewhere got the idea," wrote Lucy Larcom in the 18th century, "when I was a small child, that the chief end of woman was to make clothing for mankind." Ellen Rollins: "The moaning of the big [spinning] wheel was the saddest sound of my childhood. It was like a low wail from out of the lengthened monotony of the spinner's life." (Jack Larkin, The Reshaping of Everyday Life, p. 26)

Anyway, with clothing that expensive and hard to make, every item was something you wore until it literally disintegrated. Even in 1800, a farm woman would be lucky to own three dresses - one for best and the other two for daily living. Heck, my mother, in 1930, went to college with that exact number of dresses to her name... This is why old clothing is rare: even the wealthy passed their old clothes on to the next generation or the poorer classes. The poor wore theirs until it could be worn no more, and then it was cut down for their children, and then used for rags of all kinds, and then, finally, sold to the rag and bone man who would transport it off to be made into (among other things) paper.

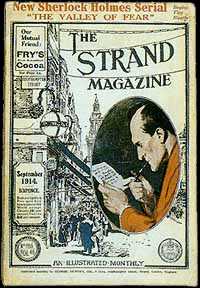

And speaking of paper, that was another thing that had to be invented for our society to exist: cheap paper. Good rag paper (made literally with expensive cloth rag) was always pricey, just not as pricey as parchment which was goat, sheep, or calf skin. (This is why medieval manuscripts were so few and why they were often kept chained up for fear of theft. It took at least a whole herd of animals to make the Book of Kells, for example. On the other hand, well-kept parchment can last thousands of years.) In fact, paper remained expensive long after clothing got cheaper, because it took a long time to figure out how to make paper out of nothing but wood pulp, without all that expensive rag content. It wasn't until the production of wood pulp paper was perfected in the mid-1800's that books (schoolbooks, fiction, non-fiction), magazines, and newspapers became available to the general public. Including pulp fiction - the first was Argosy Magazine in 1896 - a genre that was named for the cheapest of cheap fiber paper that it was published on. And without that pulp paper, where would our entire genre be?

Fascinating stuff, Eve. By the way, have you looked at the bottom of page 188 of the July August issue of AHMM? It is worth your while.

ReplyDeleteEve, history was a subject that didn't interest me at all when I was younger. I even took eight semesters of the Russian language to avoid college history in my undergraduate days. If I'd had history teachers like you, I would have developed an interest long before I did!

ReplyDeleteTerrific.

ReplyDeleteIn the 1920's when my dad was first in the States, a working man had three shirts- one on, one in the drawer and one at the laundry.

Eve, interesting, thanks for the information.

ReplyDeleteRob, I hadn't - I was too busy reading your story, which was great. But wow! That made my day.

ReplyDeleteFran, glad you liked it - more history posts will be coming.

Janice - just like my mom...

Delightful! Your creativity is amazing!!! Thelma Straw in Manhattan

ReplyDeleteThis is a fantastic post! Thank you so much for sharing such precise information in such a fascinating way!

ReplyDeleteEve,

ReplyDeleteWhat a great post! The things we take for granted today. And I learned why spinsters are called that. You make history interesting--not an easy task. My college history professor was a rare one who could to that.

Thanks for the lesson.

Nice article, Eve! I’m surprised weavers and spinners didn’t deck Ned Lud. Hmm… there’s a potential murder mystery.

ReplyDeleteI wish you could have met my Aunt Rae who was a professor of art, history, and civilization at FIT, Fashion Institute of Technology. This dovetails with her writings.

What a wonderful post!

ReplyDeleteAbsolutely fascinating!

Thanks, Eve.

--Dix

Eurocentric though?

ReplyDeleteNot as a criticism, just as a statement that this analysis is... slanted in a certain way.

Needing fabric for clothing is not Eurocentric. I think the first spinning wheel was invented outside of Europe, maybe in Asia somewhere. The earliest known clear picture of a spinning wheel is from Baghdad.

DeleteHow easily we forget how hard life was.

ReplyDeleteEverything is being improved all the time, thanks to the entrepreneur.

If I'm not mistaken, 6 yards is 216", not 72", so that would almost triple your estimated price for the shirt! Is that correct?

ReplyDeleteloved the post - we take so many things for granted - we forget how we got here

ReplyDeleteI like the end 'Pulp Fiction' reference.

ReplyDeleteShalom. It's funny that Americans love to complain about cheap Chinese "craps" but they never stop buying them. I guess it's because they are hypocritical cheapskates that love to whine and pretend being 'holier than thou' while doing the opposite. But mark my word, the moment China raise their prices because of improving qualities, raising wages, better regulations that increase costs, and whatnot, the Americans will then buy shits from somewhere else, like Bangladesh (oops, it's already happening with textiles), and then complain about human rights violations and low wages of that new place!

ReplyDelete"Then Mary got out a suit of his clothing that had been used only on Sundays during two years—they were simply called his "other clothes"—and so by that we know the size of his wardrobe."

ReplyDelete--Tom Sawyer, Mark Twain.

Wonderful stuff. Even more wonderful is the fact that I was alerted to this blog by my son, which makes me feel I have done somethung right.

ReplyDeleteAnonymous, yes this is slanted, but it originally came from a lecture I gave on the Industrial Revolution in the West, to explain why textiles were the first things to be manufactured in factories: because cloth was so expensive.

ReplyDeletehn_visitor - your math is right! The shirt was even more expensive...

The hand-made world was indeed very different, much sparser when it came to "stuff" - on the other hand, most of what you had lasted. Except candles...

Checking actual figures in 1710 (because I happened to have a price of 17s quoted for an actual shirt on hand) that's about 13 days of day labor at 16p/day (from rootsweb). Which, assuming that's minimum wage and they worked a 10 hour day, comes to about $900.

ReplyDeleteStill pretty amazingly expensive.

The weaving calculations don't make any sense. And 12 threads to the inch is not a fine weave - it's a very rough weave. Plus, you don't need 2 yards for tie up - it's more like 30 - 36 inches. And you don't need as much yarn for the weft as for the warp.

ReplyDeleteA 36 inch wide, 4 yard warp with 1 yard for tie up and 12 threads per inch would be:

36*12*5yd = 2160 yards for the warp and about 4/5 that much for the weft, for a total of 3888 yd.

As for spinning, 4 yards and hour is way too low a number. That's 15 minutes to make one yard of yarn! Anyone that slow would starve!

And BTW, I know a weaver who weaves 4 yards / hour. I can't, but she can. 12 picks per inch is pretty fast to weave. Now, if it really were "fine cloth" it would be 30 to 60 threads per inch.

ReplyDeleteThe high cost of fabric often led to disputes over the ownership of the scraps between the tailor and client and one could be hanged for stealing remnants.

ReplyDeleteYou forgot costs included in grow flax and preparing linen prior to spinning.

ReplyDeleteSpinning 4 yards/hour is way too slow.

Flax is much faster to spin than cotton. But you have to include the hours of time and the equipment to ret the flax and hackle it. Retting flax was some of the earliest water pollution, I believe.

ReplyDeleteGood day, I was looking over this and I had the following comments

ReplyDelete1) I think that the minimum wage assumption makes this a difficult piece, it seems that labor cost increases did not occur until the industrial revolution. Even very specialized laborers also used low cost assistants / apprentices. The actual minimum wage in that period might be something on a subsistence or near subsistence level of approximately 1 - 2 dollars a day for individuals that labored in this manner, and that would be in their dollars not present dollars (which may have been pennies a day). The current costs utilize similar international (also often exploitative) wage differences in addition to a mechanization of production. The poor individuals in Bangladesh may also be making the same subsistence or near subsistence wages, last I checked the minimum wage there was $36 a month, or little over $1 a day. You can use the link below to make it accurate estimate based upon real wage costs. It appears the hourly wage in nominal dollars in 1790 was $0.02.

http://www.measuringworth.com/datasets/uswage/result.php

2) all other production at the time appeared to be subject to the same or similar labor intensive constraints, so all goods and services would have probably corresponded in value, including food since the agricultural revolution had not yet occurred.

So while the relative value of that shirt in todays labor applying todays minimum wage would have been $3,500 or more. The actual cost of that shirt at the time would have been much lower due to very large differences in labor costs. These differences are clearly due to oppressive systems (slavery, not valuing women's work, and serf systems). So your estimate would probably have to be tempered with that labor pricing in mind.

I don't know if times have changed or people just have more money, but growing up in the 70s, I had 1 dress, once I outgrew it, it became a shirt that you wore with pants (that fashion came back some a couple of years ago. I hated it.) Only then would I get another dress. Shirts? Maybe 3. Pants? 1. The end. And that was the standard until...wow, it wasn't until I was in college and was able to save and buy a new item every so often. Don't even ask about underwear. I had my mom's hand-me-downs for years. Up until college, yup, I still had the one and only bra my mom gave to me, after being worn by her for years. Know what? It still held it's color and shape after something like 20 years of constant use. Try that with something bought today?

ReplyDeleteThank you all for your comments. A couple of factors with the weaving (and I have been a weaver myself) - some weavers are faster than others. And, in America at least, colonial and pioneer women were often expected to weave their own cloth at home "in between" other chores, which means it would take a much longer time for them to accomplish their tasks.

ReplyDeleteAlso, regarding tie-up, a professional weaver was indeed expected to present the completed piece with the tie up attached, so that one tie-up would not do for more than one person's job; and, considering the size of some looms of the day, it could take a yard on each side to tie up, especially when you include the first few inches of spacing slats and weft.

I always told my classes that this did not include the actual growing/raising/manufacturing of the raw materials (flax, cotton, wool), which was another whole level of expense.

Finally, the whole idea of translating it into modern monetary terms was to show the percentage of income (or time) it would have taken to buy/have made a shirt in pre-industrial times. Time is time - 479 hours today is almost 12 weeks' work. Back then, it was about 8 weeks' work (perhaps more, because they had more holidays than today's worker). That's a lot of time (or its equivalent in money) to devote to getting one shirt. As always, it means that those who did the most of the grunt labor, like spinning, had the least ability to buy any of what they made.

As I've said before, I think this is an excellent object lesson in why the first thing to be produced by the factories of the industrial revolution was textiles. No matter how you slice it, they were incredibly expensive!

Cinnamon, that's really poignant. We don't usually think of hand-me-downs from parents, but they happen.

ReplyDelete4 yards an hour? I can spin 2.5 yards a minute on a hand spindle, and unlike spinners in medieval times, I haven't been doing it my entire life or optimizing for efficiency. Those numbers aren't quite right.

ReplyDeleteLOVE THIS!!

ReplyDeleteCurrently featuring it at the top of our financial site right now:

http://rockstarfinance.com

A great thing to keep in mind when we're all bitching about how "bad" it is these days! Great great post, thank you :)

Very enjoyable article and I am delighted to find a site where the entire comments section contains no ad hominem insults. Congratulations to all!

ReplyDeleteBarbara Tuchman wrote "A Distant Mirror" in the 1970s as a comparison of the middle ages and the anxieties that the western cultures were experiencing at the time, which was (to me) an excellent use of reading time.

It is really amazing how automation has turned necessities into commodities. We spend substantially fewer hours on clothing and food than we did even just 100 years ago

ReplyDeleteThis graphic illustrates it really well

http://visualizingeconomics.com/blog/2013/11/18/100-years-of-family-spending-in-the-us

Most of our spending in these categories is now recreational

Thank you for all your comments! After talking with various weavers and spinners, I have updated the math - but it actually increases the cost of the shirt, which doesn't surprise me. Please see my update at http://www.sleuthsayers.org/2015/01/is-time-money-or-is-money-time.html

ReplyDeleteThanks!

You forgot to mark up the prices too. No one sells things at the lowest cost of labor. There was always a middle man or multiple middle men from beginning to end. Your $3500 shirt probably would be over $5k by the time it hit the general store.

ReplyDeleteHave you mixed feet with yards? I used to dressmake, 4 yards is

ReplyDeleteA lot for shirt. Although 4 feet seems small when extra 2 added that's 6 or 2 yards and your calculation of 72 inches is correct. Also, it seems as if you say mediaeval shirts were made of cotton, there weren't they would be linen. Although I am now wondering when cotton would have been easily available? Interesting article though.

"1) I think that the minimum wage assumption makes this a difficult piece, it seems that labor cost increases did not occur until the industrial revolution. Even very specialized laborers also used low cost assistants / apprentices."

ReplyDeleteIn the research I've done (17th-18th centuries), contracts often required craftsmen to provide apprentices with clothing. Servants were also often given clothing, not necessarily according to a contract but it was considered part of their salary to be handed down clothes or given gifts.

Also, it would probably take a seamstress between thirty and forty hours to make a shirt. I've handsewn a few shirts and it always took me longer, but I'm not that skilled.

Okay, enough nitpicking. This is a terrific article and the sort of history that there should be more of.

A wonderful article! But two notes: Wikipedia notes the yoke wasn't invented till the 19th century. (With a reference!)

ReplyDeleteAnd the spinning wheel was invented around the 11th century -- imagine the work to make a shirt spinning with a spindle!

I'd like to chime in on the topic of spinning. A hobby spinner with some practice can produce a few yards of yarn within a few minutes - on a spindle. A spinning wheel is even faster than that. Now, spinning one thread does not give you a finished yarn, there might be plying involved, maybe also washing and fulling (but weavers might use the yarn straight from the spindle). The fibre also usually has to be prepared before you can spin it (carding or combing), especially if you want a fine smooth thread. Without knowing more about the source you quoted, it is hard to tell what exactly they did at the quoted Dark Age site and how they arrived at that number.

ReplyDeleteHowever, a general problem with these things is the skill gap. An experimental archaeologist who plays around with a spindle will never reach a speed (and quality) comparable to that of ancient and medieval spinners who started to do this as very young children.

It would be far more useful to look into cultures where until very recently spindle-spinning was still an everyday activity, like in some parts of South America or Asia.

Nevertheless, it is true that spinning was the most time-consuming part of textile production. I think for medieval Europe the general assumption is that an average household had one loom, and almost every household member had to do some spinning to keep the weaver(s) busy.

Even in the Industrial Revolution, spinning machines were lagging behind because they were more complex and challenging than mechanical looms, and the production process was slowed down by that.

I'm glad to see that other spinners have commented on the time to spin 4 yards. I thought it just couldn't be right as I started spinning on a drop spindle in my 50s and can do WAY more than 4 yards in an hour on the spindle.

ReplyDeleteThis is a very misleading article and poor history.

ReplyDeleteThe labour cost of making a $14 shirt today is 12c in Bangladesh. Nobody is earning anything like $7.50 an hour. Similarly, nobody was being paid the equivalent of $7.50 to make clothing before industrialisation.

The implication that because we would have to be paid at least $7.50 an hour today to make a shirt means clothing was ridiculously expensive in pre-industrial times is absurd. Most people made their own clothing inexpensively. If they hadn't, we would be talking about nakedmness.

One major flaw with this. No one pays for every aspect of a product in one lump sum. The spinster pays for the thread to spin then sell that to whomever needs it. The next person pays for the thread and makes it into something. The next person pays for whatever is made. So there isn't that ridiculous lump sum payment at the end. The costs are divided among each level of manufacture. For someone giving an economics lecture, this is seriously flawed with the assumption that all production costs come due at the end for one individual which simply doesn't happen, except when someone makes and sells something themself (ie farmer growing fruit and selling it at side of the road fruit stand).

ReplyDeleteWonderful article.

ReplyDeleteI was wondering if you'd be willing that I'll translate it to publish in my blog (it's in Hebrew) and credit you?

Tom, please feel free to translate it to publish in your blog (with credit). I'm honored.

ReplyDeletePeople have been saying spinning is "way faster" - but let's put a number on it.

ReplyDeleteI'm a very amateur spinner, and I can do about an inch per second. That's 60" or five feet per minute, or 300 feet / 100 yards per hour.

9000 yards might then take 90 hours, not 500 - for a rank amateur.

A friend of mine who's an amateur historian, historical re-enactor, weaver, spinner, and carder, said that as a general rule it took two people spinning for every one person weaving, and two people carding (with hand cards) for every one person spinning.

Others have questioned your figure of 72 hours for weaving. Here's a personal account of someone weaving 4-6 yards in a 10 hour weaving day. http://www.xmarksthescot.com/forum/f254/how-long-weave-8-yards-tartan-68046/

So if it took 10 hours to weave your shirt, 20 to spin, and 40 to card, that adds up to a bit over 1/10 your hourly estimate.

In short, please find more sources than the one you are relying on, and adjust your article accordingly.

very informative :) thanks,

ReplyDelete@chris phoenix

ReplyDeleteI think the truth lies in the middle, probably. I doubt that two spinners are really enough for one weaver, unless they are specialists and do nothing else. That's not something that was the norm in medieval times. Especially not with a hand spindle, which was usually used in the times you didn't need to do anything else. After all, most women in the household had to spin whenever possible, so one person could weave.

But still, just think about it: Even if a shirt would take about "only" about 60 to 100 working hours ... It's still an enormous number. A person actually has to find the time to do all that work.

Insofar I agree with Eve: wir appallingly ungrateful. I use my craftsknowledge regularly to show my pupils a little bit, just how much we live in paradise. Sure, they won't really think a bit more about resources, environement and so on right then, but maybe, just maybe they will, when they've grown up. They certainly notice, that making a yarn with a handspindle takes quite a bit of time ...

@chris phoenix

ReplyDeleteI think the truth lies in the middle, probably. I doubt that two spinners are really enough for one weaver, unless they are specialists and do nothing else. That's not something that was the norm in medieval times. Especially not with a hand spindle, which was usually used in the times you didn't need to do anything else. After all, most women in the household had to spin whenever possible, so one person could weave.

But still, just think about it: Even if a shirt would take "only" about 60 to 100 working hours ... It's still an enormous number. A person actually has to find the time to do all that work.

Insofar I agree with Eve: wir appallingly ungrateful. I use my craftsknowledge regularly to show my pupils a little bit, just how much we live in paradise. Sure, they won't really think a bit more about resources, environement and so on right then, but maybe, just maybe they will, when they've grown up. They certainly notice, that making a yarn with a handspindle takes quite a bit of time ...

Thank you, anonymous.

ReplyDeleteAnother factor is that that almost no one spun full-time - women were the spinners (spinsters), and it was no hobby: it was what they did in between the baking, brewing, cooking, sweeping, cleaning, washing, tending the dairy, the fowl, the garden, having babies, tending the babies, the small children, the sick, and doing the work they owed to the local lord. Spinning was tucked in here and there, and it was, probably, almost universally despised - in Grimm's fairy tales, every young girl HATES spinning.

I really enjoyed reading this article, despite all the comments of cost calculations, I find it amazing hope people of this day and age take things for granted and do not pause and reflect how we got here and how life was a couple of centuries ago. we as human should be very grateful to everything we have and be mindful of all the blessing we have.

ReplyDeletepretty cool ig

ReplyDelete